April 2025

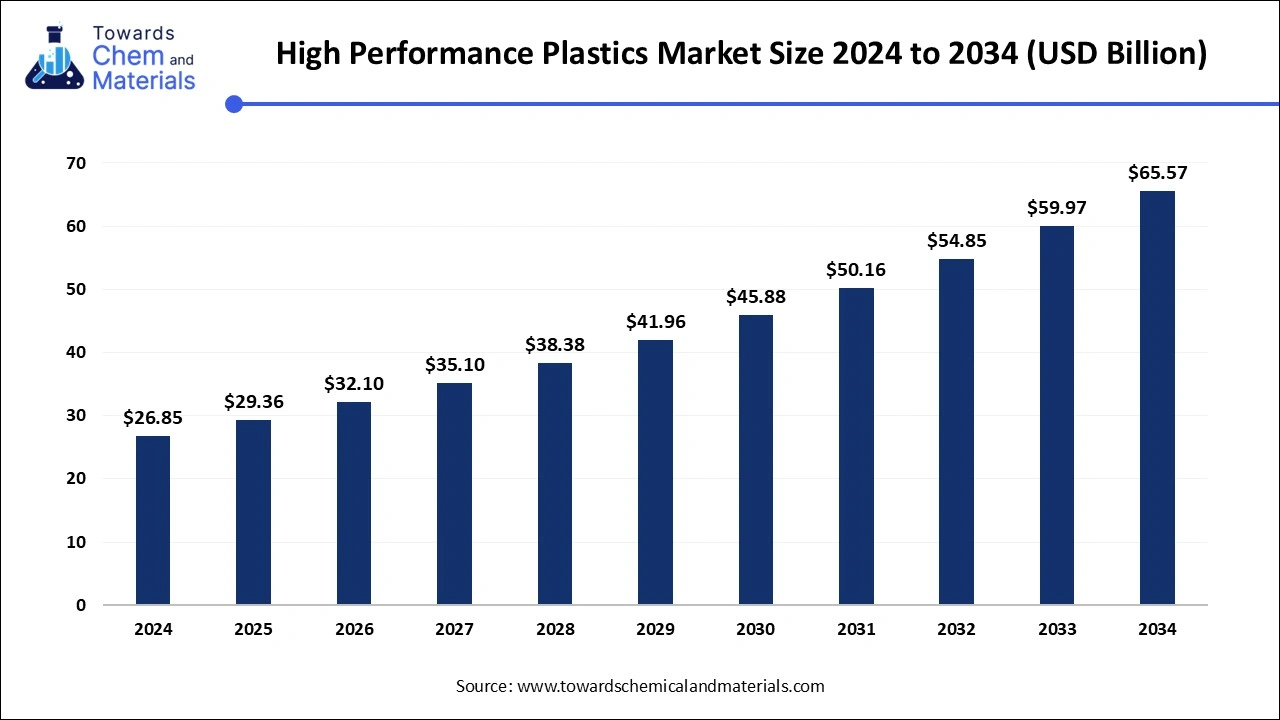

The global high performance plastics market size was valued at USD 26.85 billion in 2024 and is estimated to reach around USD 65.57 billion by 2034, exhibiting a compound annual growth rate (CAGR) of 9.34% during the forecast period 2025 to 2034. the demand for high-performance plastic is growing due to excellent performance at high temperatures and highly reactive chemicals. The rising trend of EVs demands high-performance plastic for battery casing, thermal management systems, and under-hood components to enhance safety and durability.

High-performance plastic provides higher thermal and chemical resistance than standard engineering plastic. This plastic sustains conditions such as high temperatures and strong chemicals without changing durability and strength. Rising applications of high-performance plastic in various in industry drive the growth of the market. The rising demand for high-performance plastic is due to its durable and lightweight properties.

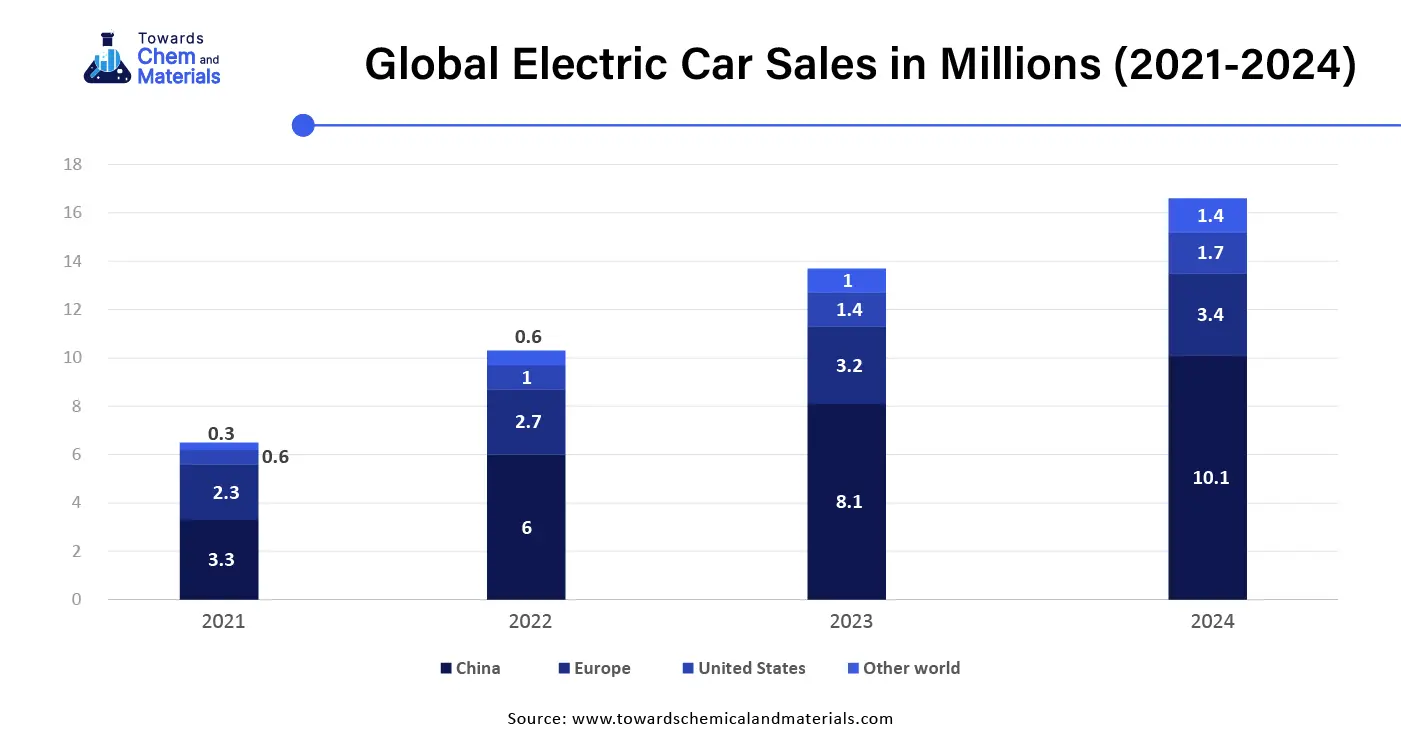

The rising market of electric vehicles drives the growth of the high-performance plastic. High-performance plastic material is used in various electric vehicle parts such as battery housing, electrical connectors, structural parts, and thermal management systems due to its strength and lightweight properties. High insulation properties of the plastic used to manufacture battery casing and housings to increase the safety of vehicles. Consumers are giving preference for lightweight and environment-friendly vehicles due to these sales of electric vehicles are growing. To resist extreme temperatures thermoplastics are used in vehicles to create materials like air ducts, fluid bottles, and many more. This material improves durability and resistance. High-performance plastics offer high strength, temperature resistance, and chemical resistance. The growing EV sale is a major driver for High-performance plastic due to its wide application and functions.

| Report Coverage | Details |

| Market Size in 2025 | USD 29.36 Billion |

| Expected Market Size in 2034 | USD 65.57 Billion |

| Projected CAGR 2025 to 2034 | 9.34% |

| Dominant Region | Asia Pacific |

| Segments Covered | Product, application, region |

| Key Companies | All4Labels; CCL Industries; Amcor Plc; Avery Dennison; Multi-Color Corporation; Mondi plc; Huhtamaki Group; Neenah, Inc; Berry Global; 3M |

The healthcare industry can enhance the use of high-performance plastic in medical devices. High-performance plastic is used in surgical instruments, implants, and many more medical problems. By using High-performance plastic, the healthcare industry can create patient-specific implants. Patient-specific devices provide consumers with greater accuracy and the shortest rehabilitation time. In the healthcare industry, 3D printers are gaining popularity, and it produces implants as per patient's requirements. High-performance plastic offers versatility and flexibility in the design of medical devices. Customizability in 3D printing devices going to boost the market of high-performance plastic. In the medical industry, high-performance plastic can be used to create prosthetics, and personalized monitoring devices for better consumer experiences.

High-performance plastic has a higher production cost than standard engineering plastic due to high thermal and chemical resistance. Manufacturing high-performance plastic requires high temperature moulding due to this operational cost increase. The cost of raw materials like polyether ether ketone (PEEK), polyphenylene sulfide, and fluoropolymers is high. The limited availability of products poses a higher cost in the market. Higher distribution and production costs are the biggest restrictions for the market.

Asia Pacific dominated the high-performance plastic market in 2024. The growing use of electronics and electrical industry drives the growth of the market. In this region, high-population countries such as India & China are present, and due to this key factor market is growing. Furthermore, rising demand for smartphones, wearable technology, and smart appliances requires high-performance polymer that boosts the growth of the market. In the region countries like South Korea, Japan & Taiwan produce advanced microchips, and this requires polymers like LCP and PEEK. To manufacture semiconductors and microprocessors high-performance plastic is used & it increases its span.

China is known as a global manufacturing hub, particularly for the electronics and automotive industry which raises demand for high-performance plastic in the country. A huge population and a widely growing economy help to grow the market. The growing demand from various industries and government support drives the growth of the market.

North America expects the fastest growth in the high-performance plastic market during the forecast period. In industries like aerospace and defence high-performance plastic is used due to its high-temperature resistant, lightweight, and durable nature. Demand from various industries like healthcare, automotive, and aerospace drives the growth of the market in the region. North America has a strong core for research & development, and they dominate in the 3D printing section which helps in the growth of the market. The availability of high disposable income and high-quality raw materials fuels the growth of the market.

The U.S. leads the global high-performance plastic market in the North American region. In the U.S. development of electric vehicles drives the growth of the market. Manufacturer uses high heat-resistant and lightweight material for battery housing, thermal management systems, electrical connectors, structural parts, and power electronics. Materials like PPS, LCP, and fluoropolymers enhance battery life and vehicle range. The demand for high-performance plastic increased due to the U.S.'s strong investment in sustainable transportation and domestic battery life fuels the growth of the market.

The fluoropolymers segment dominated the high-performance plastic market in 2024. The market is growing due to its high usage in industries such as medicines, transportation, and many more. Fluoropolymer has high thermal stability, low friction, and exceptional chemical resistance. This polymer is used for water processing equipment, high-purity fluid handling components, and chemical storage. Due to its strong electrical insulating properties, this polymer is used in industries like semiconductors and electronics. Whereas liquid crystal polymer segment is expected to witness the significant growth of the market during the forecast period. The fast development of IoT systems and 5G networks drives the growth of the market. The LCP possesses great stiffness, mechanical strength, dimensional stability, flow, and high-temperature resistance. LCP has excellent electrical properties and high-frequency signal transmission capabilities due to this it is widely used in electrical and electronics components such as connectors, circuit boards, and antennas. LCP transmits data at high speed with the least loss of energy.

The transportation segment holds the largest share of the high-performance plastic market in 2024. The wide application of high-performance plastic in manufacturing automobile parts drives the growth of the market. The utilization of high-performance plastic in vehicles makes them reliable, flexible, and lighter in weight. To minimize carbon emissions and enhance fuel efficiency manufacturers use lightweight high-performance plastic material. Moreover, Polyether ether ketone (PEEK), polyimides, and polyphenylene sulfide (PPS) replace interior components, metal, and under-the-hood components due to properties like durability and high thermal resistance. Whereas the electrical & electronics segment expects the fastest growth in the market during the forecast period. The market is growing due to superior insulation, high resistance, and customization for specific applications. Polymers like polyetherimide and polyaryletherketone are used in devices like smart wearables and power-hungry processors due to their flame resistance, thermal stability, and dielectric strength.

By Product

By Application

By Regional

April 2025

April 2025