April 2025

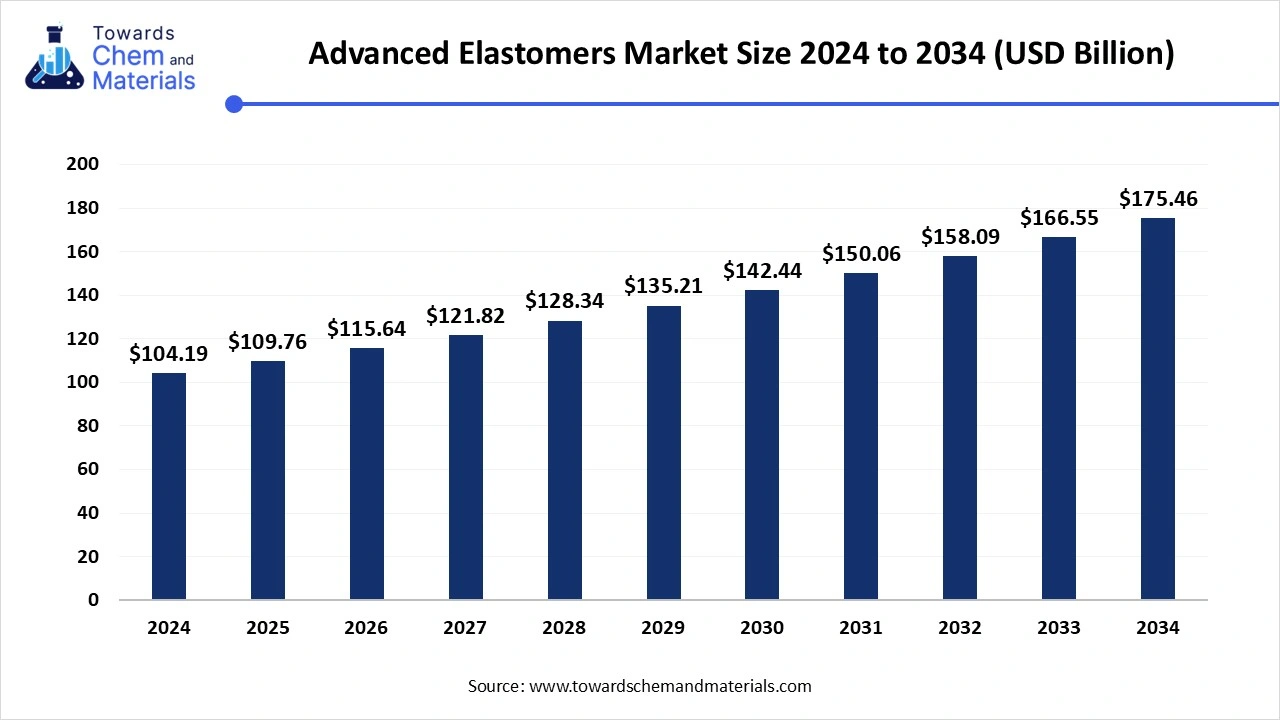

The global advanced elastomers market size accounted for USD 104.19 billion in 2024 and is predicted to increase from USD 109.76 billion in 2025 to approximately USD 175.46 billion by 2034, expanding at a CAGR of 5.35% from 2025 to 2034. Awareness of the market has increased amongst consumers, driven by enhanced elasticity, durability, chemical and heat resistance, and superior mechanical performance. They are specifically engineered to improve mechanical properties across a range of applications.

The advanced elastomers market is a high-performing segment within the advanced polymers industry known for its flexibility, durability, and resilience. These key characteristics make electrodes ideal for demanding applications. Designed to remain elastic even under harsh conditions such as extreme heat, chemical exposure, and physical stress advanced electromers are widely utilized across aerospace, medical devices, automotive electronics, and consumer goods industry.

Typically, these materials are used in flexible components such as gaskets, hoses, and seals. A major growth drive pushing the market to the forefront is the development of thermoplastic bio-based electromers and the adoption sustainable manufacturing techniques, aligning with the global shift toward eco-friendly solutions.

Moreover, these electromers offer superior properties such as high elasticity, thermal and chemical resistance, durability, and mechanical strength, making them ideal for challenging environment and precision application, resulting in rising consumer awareness of long lasting and reliable materials.

| Report Attributes | Details |

| Market Size in 2025 | USD 109.76 Billion |

| Expected size in 2034 | USD 175.46 Billion |

| Growth Rate | CAGR of 5.35% from 2025 to 2034 |

| Base Year in Estimation | 2024 |

| Forecast Period | 2025-2034 |

| High Impact Region | Asia Pacific |

| Segment Covered | By Product, By Application, By End Use, By Region |

| Key Companies Profiled | Dow Chemical Company,Lanxess AG,BASF SE,Kraton Polymers,Chevron Phillips Chemical Company,SABIC,Wacker Chemie AG,Mitsui ChemicalsArkema S.A., Momentive Performance Materials |

The advent of additive manufacturing, also known as 3D printing, is transforming the way silicone and elastomer are conceptualized, fabricated, and applied. Renowned for their elasticity, long-lasting performance, and tolerance to extreme environments, silicones are finding increased utility in advanced production. a significant hurdle in this area is the formulation of silicon compounds that are fully compatible with 3D printing technologies. Due to their adaptability, silicones are particularly suitable for producing intricate and tailor-made components through additive methods.

A major obstacle in the elastomer industry is the development of eco-friendly alternatives that can replicate the high-performance traits of convectional synthetic variants. Typically sourced from petrochemicals origins, synthetic elastomers are favored for their robustness, enhanced structural integrity, and resilience against chemical degradation.

Such materials are indispensable in high intensity industrial settings, due to their exceptional tensile property, malleability, and resistance to aggressive conditions. The primary encounter of achieving bio-based elastomers lies in gauging the mechanical performance and consistency. The materials of bio-based elastomers can vary depending upon their source and processing methods.

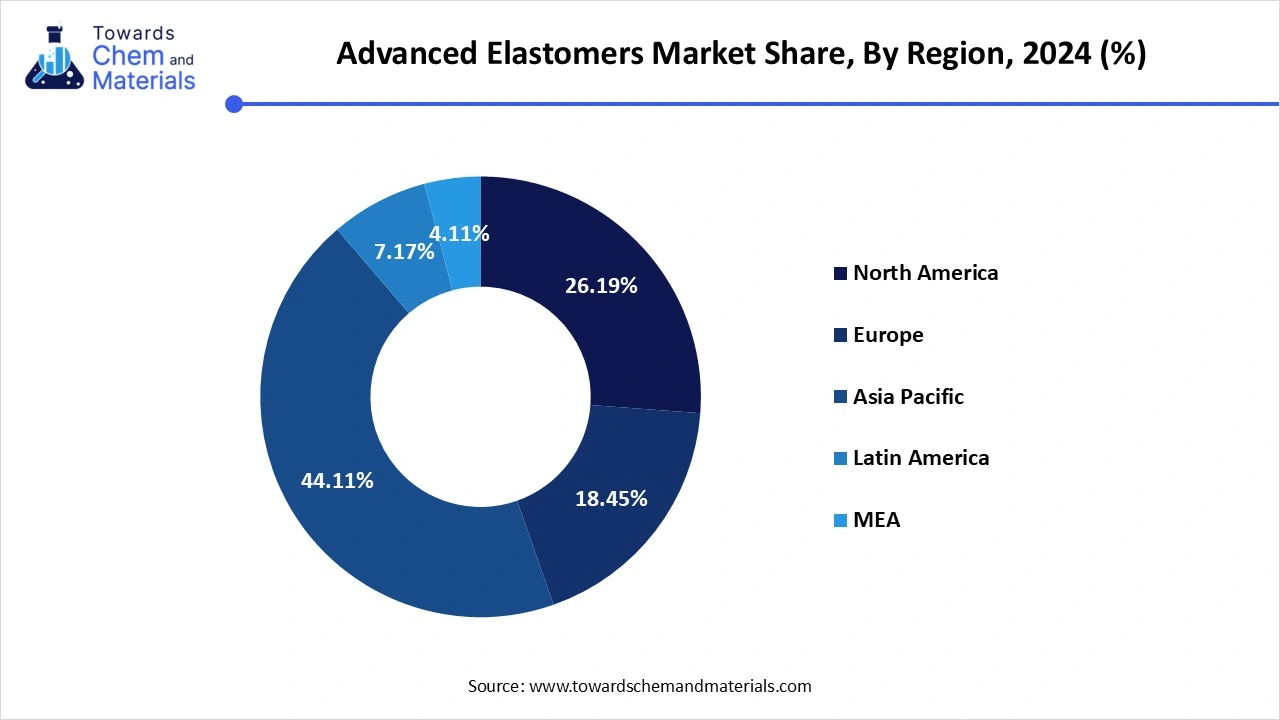

Asia-pacific dominated the advanced elastomers market in 2024. The growth of the market is attributed due to rapid industrialization, rising automotive production, and significant investments in infrastructural developments.

The key contributing countries such as China, India and Japan are witnessing a rise in elastomer market due to a sudden surge in manufacturing. As well some governments initiatives, has been initiated for promoting electronic Vehicles in these countries.

Healthcare industry in Asia-pacific is prospering due to increase in demand for medical implants, flexible electronics, and wearable devices. It is predicted that this region will dominate the market in upcoming years.

Availability of raw materials and low-cost labor makes the region a global hub for elastomers manufacturing. As well a surge in vehicle has been observed due to production and demand for lightweight, durable components boosts market growth.

Increasing demand for medical devices and implants made from silicon elastomers is the factor dominating the market. like for example in covid times the use of oximeter had increased to check the oxygen levels or for instance lets take an example of sugar checking machine a person can be aware about increasing or decreasing sugar levels. All these factors and especially rising focus on R&D is contributing towards the dominance of this region.

North America is anticipated to have significant growth in the advanced elastomers market in the forecasted period, due to increasing global focus on sustainability, advancements, healthcare, pharmaceutical industries, and significant investments in R&D and advanced manufacturing techniques. U.S., Canada, and Mexico serve as the key market players, because of supportive government policies and growing investments in bio-based sustainable solutions.

Pharmaceutical industry being an emerging player in North America has expanded the chances of getting proper medications during emergencies, as well has increased the purchase of many medical devices to be an early indicator. This has expanded manufacturing capabilities and favorable trade regulations.

High demand for medical-grade silicone elastomers for use in implants, catheters, and surgical devices. A surge in adaptation of advanced material and fuel-efficient vehicles has been witnessed in this region. Increased use of elastomers in robotics, electronics, and aerospace due to their thermal and chemical resistance.

Government support for sustainable materials and investments in high-performance polymers is increasing. Also, this region is encouraging the replacements of convectional materials with eco-friendly elastomers. Especially in U.S. is leading in high-performance automotive engineering.

The thermoplastic elastomers (TPEs) segment dominated the advanced elastomers market in 2024, the market is witnessing growth, due to its versatility, recyclability, and ease of processing. Their wider adoption in automative, industrial, and ease of processing. They are widely used in medical devices, due to their flexibility and ease of processing. Reason for adoption in automotive, industrial, and consumer goods continue to drive their dominance in this market.

The silicone elastomers segment is anticipated to have significant growth in the advanced elastomers market during the forecast period due to their superior flexibility, heat resistance, and compatibility with sensitive applications such as medical and electronics. Their increasing use in healthcare, electronics, and automotive applications is driving growth in the market. Increasing use in drug delivery systems and diagnostics tools also contributes to their rapid expansion.

The insulation segment dominated the advanced elastomers market in 2024, it is witnessing growth, especially in electric and construction industries, due to their excellence and delicate properties. Used extensively in medical tubing, wires, and electronic components, especially in environments that require sterility and durability. It plays a vital role in medical electronics and biotech instrumentation.

Implants segment anticipated to have significant growth in the advanced elastomers market during the forecast period, driven by advancements in biocompatible martials and increased demand for customized medical solutions. The rising demand for medical implants, such as catheters, pacemakers, and prosthetics, especially in ageing populations and advanced healthcare systems, is fueling segment. The key factor contributing towards the growth of this segment is ageing population, growing prevalence of chronic diseases and technological advancements.

The industrial sector segment dominated the advanced elastomers market in 2024 it is witnessing growth, due to consumers of elastomers utilizing them in seals, gaskets, hoses, and various high-performance components. The sector demands for durable, high-performance materials contribute significantly to market expansion. Their durability, flexibility and resistance to environmental stressors make them ideal for industrial insulation and sealing applications.

The medical Implants segment anticipated to have significant growth in the advanced elastomers market during the forecast period. The growth of the segment is owing due to adoption of elastomers, particularly in diagnostics, drug delivery systems, and wearable health devices, due to their safety, flexibility, and precision. The segment is growing due to rising healthcare investments, demand for biocompatible materials and stringent safety standards in medical device production.

By Product type

By Application

By End-use

By Regional

April 2025

April 2025

April 2025

April 2025